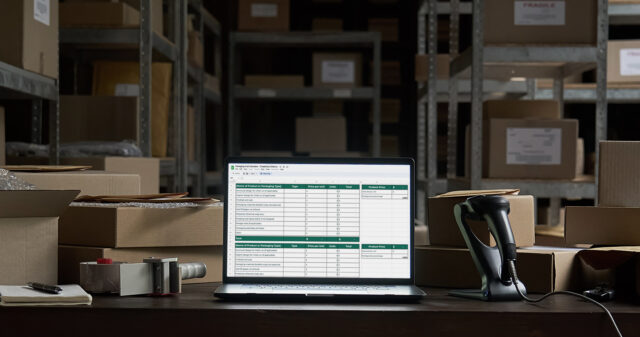

How to use our packaging cost calculator

Use the packaging cost calculator below to estimate costs for product packaging, including the following fixed and variable costs:

- Design

- Construction and labor

- Materials

- Packing components

- Shipping

- Storage

The cost calculator is flexible enough to estimate the cost of different package materials and components of the total packaging cost. It can also show packaging costs for different configurations and review packaging as a percentage of product pricing. It allows you to see at-a-glance totals for each packaging type.

To download the packaging cost calculator:

- Click here to access the Google Sheets template.

- Save a copy of the template to create your own product configurations and cost tracking.

- Fill in the columns with estimates or quotes. Calculations will appear in the totals columns.

Download the free tool: Packaging Cost Calculator

Do you need custom packaging?

Suppliers offer a lot of options for creating custom packaging. But before you begin making branding decisions on an expensive custom design, it’s important to know whether custom is the right move for your needs.

The first step to estimating and controlling packaging costs is knowing whether off-the-shelf packaging could work for your project. Understanding product sizes, specifications, value, categories, and markets can help you choose between prefab options and custom work. A cost calculator makes it easy to see how custom versus standardized varieties affect package presentation, quality, and shipment protection.

Answer the questions below to determine if custom packaging is the best choice for your needs:

What product type are you packaging? Packaging for different types and categories of products varies widely. Certain categories of products, such as cosmetics, foods, or age-restricted substances, may require packaging that meets regulations for tamper-proofing (such as a freshness seal), access restriction (such as child-proof lid systems), or food-grade presentation. Depending on the type of product and its shelf life, durability, sensitivity, or cost, there may not be an off-the-shelf packaging solution available.

What are the product dimensions? Knowing the precise size of shipped items can help determine if standard packaging options are suitable or if custom sizing is necessary. Items that don’t fit into standard packaging sizes will need customization. Sizing considerations can also help streamline packaging into fewer types to avoid needing a separate package (and its associated design costs) for every product or purpose. Shippers will also want to account for display needs, such as hang-tag packaging for hanging presentations.

How much product protection do you need? Delicate items or products prone to damage may require customized protective packaging like thermal shrink wrap to maintain their condition in transit. Other protective options include waterproofing, insulation, or security seals for perishable or temperature-sensitive items.

Do you need custom graphic design? Custom packaging offers opportunities for unique branding, which can elevate customer experience and brand recognition. If the packaged product is of high value, a custom design will enhance the product’s presentation quality and improve customer experience.

What is your product volume for each packaging type? Volume pricing makes custom packaging more cost-effective by providing volume-based discounts. If you ship a high quantity of items in a specific package type, custom packaging might be a more affordable option.

What shipping requirements do you have? Some packaging (for instance, a display box for a bespoke snack subscription) can double as a shipping container for certain products. In these cases, the design must meet dimensional requirements for the shipping service used. If shipping internationally, remember different countries have various regulations and standards that call for custom packaging. Understanding how (and where) packaging will be used can determine the level of packaging needs.

What are your sustainability concerns? Many customers prefer using brands with sustainable practices. Custom designs can incorporate eco-friendly materials and processes if sustainability is a priority. In some cases, eco-friendly packaging may lower the cost of packing materials.

What is your design and materials budget? Understanding financial constraints can help you tailor a custom packaging solution to meet your needs and spending requirements. With a clear understanding of packaging project requirements and budgets, you can seek high-quality suppliers to balance presentation standards, regulations, and costs.

By answering the above questions, product manufacturers, retailers, and shippers can better assess the need for custom packaging solutions that meet product needs and enhance the brand.

How to quickly estimate your cost for packaging

If you’re trying to get a feel for the cost of packaging an item, this formula will give you a basic idea:

Packaging Cost per Unit = (Cost of Packaging Materials) / (Number of Units)

This simple formula doesn’t factor in considerations like design fees or volume discounting, but it can provide a good starting point for understanding how much packaging could cost for a set number of units. It provides a place to start when establishing a budget or working on product marketing.

Fixed and variable costs for packaging

Packaging quotes have several fixed and variable costs for the total price per packaging unit. For a more detailed cost assessment, you must look at the factors that make up bottom-line per-unit pricing. Some of these, like design services, stay the same regardless of order value, print run size, or purchase volume.

Variable costs, like materials selection, labor, shipping, and assembly, are directly tied to order levels. Both types of costs influence the overall expense of packaging products. Understanding the balance between fixed and variable costs helps businesses optimize their packaging strategies while maintaining efficiency and sustainability.

Fixed Costs

Structural design and prototyping: Physical package design involves creating the package's physical layout and producing initial models for testing. These costs remain constant regardless of the number of units ordered. They represent essential investments in developing a full packaging design solution tailored to specific product needs.

Graphic design and branding: Graphic design and branding are fixed costs when creating a new package type or configuration. The design lays out the visual elements of packaging, like logos and color schemes, as they appear on the package. These aspects are essential for creating a brand identity. They are considered a fixed, upfront investment.

Setup costs for printing and tooling: Printers must set up printing and tooling equipment for each custom print job. Setup costs defray the expenses associated with preparing machines and creating tools necessary for producing custom work. These upfront investments are fixed, meaning they do not fluctuate with the quantity produced. Accounting for setup costs helps ensure each unit maintains uniform quality and appearance.

Variable Costs

Cost of raw materials: Construction components of packaging, including cardboard, plastic, and ink, are necessary for packaging development. These materials represent a significant variable expense. Material costs fluctuate based on market prices and the quantity of materials required for production, making budgeting for them unpredictable.

Labor costs for assembly and packaging: These are wages paid to workers for assembling and packaging products. This variable cost is influenced by the complexity of the packaging process, the amount of labor required, and prevailing wage rates. Labor can significantly affect the total cost and varies with the scale of operations.

Shipping and handling charges for materials: Depending on supplier agreements and volume, transporting materials for packaging production, you may have to pay to transport materials to your warehouse or location for use. These expenses vary with distance, shipment volume, and speed, directly impacting costs. Efficient logistics planning can mitigate these variable costs. Lead times and processing speed may also figure into the total cost of purchasing package components.

Volume discounts: Many suppliers offer price reductions when purchasing large quantities. For packaging, this means the cost per unit decreases as the quantity ordered increases, allowing businesses to save money on bulk orders. This pricing strategy can significantly lower the overall cost for companies requiring large-scale packaging solutions.Packaging delivery costs: These are expenses linked to transporting finished goods from facilities to their final destination. Delivery costs vary based on distance, volume, and transportation method, making them less predictable than fixed costs.

How much should small to midsize businesses spend on packaging?

Many industry sources say businesses should estimate packaging costs as a percentage of the item's per-unit cost. While some general sources reference percentages between one and 10 percent, this general guideline doesn’t accurately account for factors like item value, industry, and special protection requirements (such as waterproofing, spoilage control, or temperature protection). The packaging cost calculator helps you consider all these factors when planning a packaging project or design.

Obviously, the more you save on packaging costs and product shipping, the higher your profit margins. Managing the total cost of packaging and shipping can help maximize returns and fund critical growth.

There are a few cost-effective ways to reduce the cost of materials when designing packaging, including choosing standardized packaging and lightweight supplies.

- Pre-set box styles and standardized packaging may be an option for products of a certain category, value, or durability. Readily available standardized packaging options can provide adequate product protection in these cases. They also offer opportunities to apply branding in a more cost-effective format. Consider using some standard elements when you calculate your total cost for packaging. Blending standardized and custom details can make shipping supplies more affordable per package.

- Lighter packaging materials, like “clamshell” molded plastic enclosures, can reduce packaging costs. You can also pack items with lighter materials such as air balloons and biodegradable "peanuts." Using light, resilient, and cost-effective materials is called “lightweighting.” It saves on packaging fees as well as shipping costs. It may also have a positive impact on the environment and can attract customers who value environmentally friendly practices in their brand selection.

How Order.co makes recurring expenses easier

Packaging materials have a lot of price variability, but there are ways to save money and ensure a high-quality presentation and customer experience. The ability to estimate costs across different vendors helps companies save money on packaging products.

Order.co gives businesses access to high-quality packaging vendors so they can find the packaging materials they need. The platform makes reordering popular consumables like shipping components quicker and easier with curated catalogs. Businesses can also use Order.co to work with any vendor they already know and love. It also has easy reorder features to help you find alternatives if your usual vendor is running low.

The Order.co platform also makes AP processes more manageable for all purchases and recurring payments. With automatic purchase order processing, automated approval workflows, order reconciliation, and automatic general ledger (GL) coding, teams can leave manual processing and uncertainty behind. Order.co allows you to save time on invoice processing by consolidating 100s of invoices into one monthly bill.

Request your copy of the packaging cost calculator today. You'll get the full picture of your packaging cost and needs, plus the ability to easily calculate and track packaging spend — all in one place.

Get started

Schedule a demo to see how Order.co can simplify buying for your business.

"*" indicates required fields

When companies are in growth mode, they often bring on a range of suppliers to meet business needs. While there’s no perfect number or type of supplier relationships, how you bring on new partners can greatly impact the experience. When done right, supplier onboarding can save money, reduce risk, and strengthen buyer-vendor relationships.

This article introduces everything you need to know about building a reliable, thorough supplier onboarding process. You’ll learn what to look for in a supplier, how to ensure you add the best vendors to your list, the steps to build a well-defined supplier onboarding process, and how technology can improve business outcomes.

Download the free tool: Vendor Scorecard Template

What is a vendor onboarding process?

Supplier onboarding is the process of evaluating a vendor and bringing them online for ordering. In the supplier onboarding process, the finance or procurement team evaluates potential vendors, assesses their risk level, and integrates them into the procurement process or purchasing platform. These steps ensure quality service and a strong vendor relationship throughout the contract.

General supplier onboarding tasks include:

- Identifying potential vendors for a specific need

- Evaluating possible supply partners based on price, terms, and compliance

- Performing due diligence and risk assessments

- Setting up successful vendors in the system for future orders

The aim of vendor onboarding is to find new suppliers that meet the company's product and service quality requirements, delivery timelines, cost-effectiveness metrics, and ethical standards.

Effective supplier onboarding streamlines procurement processes and avoids costly third-party risk factors. The process allows companies to foster strong relationships with suppliers, improve communication, enhance negotiation outcomes, and boost procurement performance. It also helps companies stay competitive and agile in a swiftly changing market.

What makes supplier onboarding challenging?

A lot can stand in the way of bringing on and building relationships with high-quality vendors. Most of the challenges can be traced back to a lack of supplier data visibility or communication.

Companies that struggle with supplier onboarding often encounter the following five challenges in the supplier onboarding processes.

No vendor criteria

Without well-defined expectations, assessing potential vendors' suitability is challenging. Failing to create clear standards and requirements for new vendors may lead to teams selecting suppliers that cause delays, provide subpar product quality, or offer services inconsistent with the company's needs. A lack of vendor criteria can strain the relationship between the company and its suppliers, complicate negotiations, and make it difficult to achieve mutually beneficial agreements.

Gaps in supplier information

Scattered and incomplete supplier information makes integrating new vendors into existing systems and workflows difficult. Without comprehensive data, teams struggle to evaluate the compatibility of a supplier's services with the company's operational requirements.

This lack of information can delay supplier onboarding, as additional time is needed to gather documents like account info, contracts, or quality questionnaires. Incomplete supplier profiles can hinder effective risk assessment, exposing the company to compliance issues.

Offline vendor order processes

While many vendors employ online systems, procurement platforms, and digital marketplaces, not everyone does. Some work off emailed purchase orders, phone orders, or even faxes. Manual ordering slows transaction times and increases the likelihood of errors due to manual data entry.

Tracking and managing orders can be more difficult with offline ordering since updates aren't reflected in financial reporting without the right tools. The absence of an automated system for these processes means buyers avoid integrating offline suppliers or creating out-of-policy exceptions for working with them.

Lack of order visibility

Without a clear view of the entire procurement process, businesses struggle to evaluate potential suppliers accurately. This may introduce redundancy into the procurement process, especially when several locations order supplies outside a centralized platform.

Decreased visibility and redundant ordering mean companies lose leverage at the negotiation table since they lack data on precise order volumes, terms, and pricing. In many cases, teams end up with more vendors than they need, increasing vendor management efforts and reducing cash efficiency.

Poor AP process management

The end of a successful supplier onboarding process is the beginning of a new vendor relationship. But, fractured AP processes can add friction to relationships with new suppliers. Manual AP processes make it harder to pay vendors on time or address issues with billing, backorders, or product delivery.

Steps in an effective supplier onboarding process

If your business doesn’t have a formal supplier onboarding process for new vendors, building a safe, centralized process is easy. Follow these steps for every new vendor to ensure you enjoy high-quality service and beneficial long-term relationships.

1. Create a procurement policy: A procurement policy is foundational to strong supplier onboarding. It establishes clear guidelines for vendor relationships and management. Procurement policies outline procurement objectives, procedures, ethical standards, and spending guidelines for different roles and departments. They ensure consistency and transparency for all who conduct procurement activities.

2. Outline supplier requirements: Setting clear expectations for suppliers reduces service quality and risk issues. Detailing these requirements can ensure the business selects suppliers that meet its needs. It can help streamline the procurement process and foster strong supplier relationships with a smaller selection of high-quality vendors.

Requirements should define every aspect of the vendor relationship, including:

- Quality standards

- Delivery timelines

- Payment terms

- Service-level agreements (SLAs)

It's crucial to communicate these requirements upfront to avoid misunderstandings later. Specify any certifications or vendor compliance standards suppliers must meet, such as ISO certifications or adherence to sustainability standards. A supplier onboarding checklist or supplier security questionnaire is a great first step in setting expectations for bringing on new vendors.

3. Conduct due diligence: Reviewing suppliers ensures companies uncover any issues that would preclude a vendor from selection. The due diligence process includes evaluating the supplier's financial stability, reputation in the market, operational capabilities, and compliance with industry standards. It may also involve checking references, reviewing past performance records, and conducting site visits if necessary.

Careful vendor evaluation and approval process helps mitigate risks associated with supplier performance. This is especially important, considering over 40 percent of companies experienced impactful third-party security breaches in the last year. Due diligence ensures businesses engage with partners that contribute positively to the supply chain's integrity and efficiency.

4. Negotiate and sign the contract: Once a business identifies the right vendor, it must negotiate aspects like final pricing, delivery schedules, quality, payment terms, and confidentiality agreements. Effective negotiation ensures both parties understand their responsibilities, obligations, and noncompliance consequences. It's important to approach this process with clear objectives, flexibility, and a focus on building a long-term partnership.

5. Collect a supplier's information: Once a business signs with a vendor, it must collect necessary contact details, including primary and secondary contact points, email addresses, phone numbers, and office addresses. While some data collection can occur through direct integration, a vendor portal, or APIs, some vendors still operate via purchase order, email, or other means. A business must document these in the system and automate vendor management and payment wherever possible to capture spend data.

In addition to contact information, companies will want to collect payment information like bank account details or preferred payment methods. This data must be accurate within the system to facilitate smooth communication and transactions. It also enables fast payment, which can help companies take advantage of early payment discounts.

6. Centralize order information: Once a business begins ordering from a new vendor, it needs a centralized way to keep track of pending and completed orders. Centralizing this information helps build streamlined processes to track orders, enhance reporting accuracy, boost supply chain management, and enable spend analysis. Data consolidation allows businesses to monitor orders efficiently, generate insightful reports, and analyze spending patterns for better decisions and financial management.

7. Set up vendor performance reviews: The supplier onboarding phase is the perfect time to set up performance monitoring. Buyers who use a systematic approach to evaluate and monitor vendor quality, reliability, and overall performance enjoy fewer issues and stronger supplier relationships.

Onboarding is also a great opportunity to establish clear metrics and KPIs for assessment, allowing companies to monitor vendor performance versus pre-defined expectations. Regularly schedule reviews to enable timely identification of issues, continuous improvement, and stronger partnerships.

Using technology to make supplier onboarding more efficient

Incorporating technology into the supplier onboarding process can streamline onboarding, making it easier and more efficient. Supplier onboarding software allows companies to automate routine tasks, such as:

- Collecting necessary documentation

- Conducting initial assessments

- Setting up vendor payments

- Conducting vendor performance reviews

- Performing spend management

Digital platforms enable seamless communication and collaboration between businesses and suppliers, ensuring parties meet requirements and timelines. A procurement management system like Order.co also supports buyers during vendor issues such as delays or out-of-stock items. With a procurement platform, buyers can quickly source a similar item from another vendor while maintaining a solid relationship with strategic sourcing partners.

A centralized platform makes it easy to route, approve, reconcile, and pay invoices. With all data in a central location, businesses can perform supplier performance reviews efficiently and ensure vendors stay compliant and competitive.

Let Order.co make the supplier onboarding process better

A procurement management solution centralizes many aspects of the supplier management process, including vendor selection, order processing, reconciliation, and payment. With Order.co, you can maintain strong relationships with strategic vendors, keep supplies in stock with fast substitutions of needed items, and process orders for every vendor you love (even if they have an offline order process). Order.co’s implementation experts make it easy to onboard your favorite suppliers.

Want to maintain great performance from all the vendors you onboard? Download our Vendor Scorecard to evaluate every supplier your organization uses.

Get started

Schedule a demo to see how Order.co can simplify buying for your business.

"*" indicates required fields

If you need a word to summarize the economic mood in 2023, “pensive” comes to mind. After the drastic market fluctuations of 2020 to 2022, we enter the new year with an over 60 percent likelihood of recession, according to leading economists.

Tech giants, previously full-steam-ahead on fast hiring and generous salaries, are now engaged in layoffs and cost-savings measures to preserve cash flow in response to this new normal. Every business is looking at its bottom line, eager for ways to tighten spending.

Download the free ebook: Choose the Right Procurement Technology With This Decision Matrix

“In a market environment of rising interest rates, sustained high inflation, and universal corporate belt-tightening, it’s more important than ever for businesses to get the most of their resources (time and money).” - Mark Skrapits, SVP of Operations, Order.co

As one of the largest centers of addressable spend, procurement departments need to optimize cash while still creating value for the organization. The good news for these procurement teams? There are plenty of ways to prepare for the coming year. In that spirit, we compiled the top five procurement trends of 2023 as well as tips to ensure economic stability for years to come.

Top 5 procurement trends of 2023

Procurement success depends on visibility, flexibility, and human performance. The most successful procurement teams aren’t just order-takers but active partners in the success of the organization at large. Procurement professionals must explore several trends to strengthen their cash position and do more with less in the new year.

Higher standards for order matching

Three-way matching has long been a staple of well-managed purchase-to-pay processes. Matching the purchase requisition to the purchase order and final invoice creates a three-legged stool of verification. It cuts down on fraud and ensures the accuracy of data.

But three-way matching is the beginning of a better process, not the end. In 2023 and beyond, look for higher matching standards incorporating more data points along the procurement journey:

- Purchase order

- Receipt of goods

- Vendor invoice

- Confirmation of payment

- Integration to accounting record

- Financing of payment

Automated five-way matching will become the standard for mature accounting practices, with six-way matching emerging for those (like Order.co) with the platform capabilities to offer it.

Five- and six-way matching incorporate valuable enhancements into the procure-to-pay process. Automated five way matching saves time for finance and accounting teams at month-end close and reduces the need to hire additional analysts & bookkeepers as the business grows. Embedding the ability to easily spread payments out over time (the sixth match) allows finance leaders to better manage cash flow, with less effort.

Tightening net terms from vendors

Only two years ago, vendors enjoyed the ability to offer extended repayment terms. Lower interest rates, better capital reserves, and generous lines of credit from lenders made it possible to extend 60-day terms to well-qualified customers without excess risk or expense.

We begin 2023 in considerably different economic conditions to pre-pandemic times. Interest rate hikes, inflationary impacts, and the looming recession push vendors to tighten their financials and improve risk management.

The consequence of these economic shifts is less wiggle room for extended terms. This will force some stakeholders to either agree to shorter terms or seek agreements with more flexible vendors.

The rise of “pay your way"

Flexible payments have become standard practice for consumer spending in the last few years. Companies like Affirm, Klarna, and Afterpay offer no- or low-interest options for making purchases and paying over time.

The same flexibility currently available to consumers will soon come to the procurement process. These “pay your way” options within established procurement platforms allow Finance to plan and adjust its spending to meet organizational goals, make the best use of cash flow, and create options for surprise expenses.

Currently, planning for contingencies means tying up cash funds in savings, keeping a line of credit, or taking a short-term loan to handle large or unexpected procurement. These methods are moderately effective but may take days to settle. As economic conditions evolve throughout 2023 and beyond, these methods will also become more costly.

A specialized payment system based on the consumer “buy now, pay later” model benefits vendors as much as buyers. Sellers can offer extended payment terms without introducing outsized expenses or risk, allowing buyers the flexibility to make needed purchases that drive forward their organizational objectives.

“B2B pay your way is going to happen inside your ERP or Procurement Software, but only with platforms that understand the finance side of procurement. You need a platform that is just as good at handling POs & invoices as it is enabling finance & accounting functions.” -Warren Brown, Head of Embedded Payments, Order.co

Full organizational alignment on spend

Talk of optimizing the procurement process often centers on C-level and director-level coordination. But to take control of addressable spend, it’s essential to consider the complete chain of users and decision-makers that move deals from requisition to completion.

In 2023, companies keen to optimize cash flow will look to full organizational alignment. This transformation regarding approach will take many forms:

- Clear and consistent documentation and communication regarding spending and budgetary guidelines

- Alignment across the organization's critical functions: Finance, Legal, Operations, Security, and Executive

- Consistent communication up the chain of command to address challenges and opportunities with the procurement process or its outcomes

- Practices and new technologies that support strong spending rationale, due diligence, supply chain management, and supplier relationships

Aligning these factors allows organizations to respond to needs and procure goods with agility and visibility. Using digital procurement solutions to drive this alignment empowers advanced methods such as strategic sourcing, sustainable procurement, and supplier performance management.

Leveraging people + technology for results

To improve procurement strategy and streamline cash flow, it’s time to reframe the people versus software debate. Savvy procurement leaders are finding ways to enhance their workforce through procurement technology that improves business processes.

Bringing your data into an automated, organized structure facilitates the work only humans can do. It empowers finance and accounting teams to perform quick and confident decision-making, informed by access to centralized data analytics.

Contextualizing these massive amounts of data is only possible with assistance from software. Businesses may need to aggregate data from a dozen platforms to bring everything together. Using technology to unify these disparate data streams into a single source of truth makes it possible to see your entire procurement organization holistically.

“A marketplace that simultaneously connects businesses with vendors and financial partners can not only create a single source of truth for all your spend data, but it can predict and perfect things like what you are buying, how you are buying, and the way you are paying over time.” -Zach Garippa, Co-Founder & CEO, Order.co

Piper Sandler points out that integrating purchase orders, invoices, accounts payable, and general-ledger accounts data creates a more multidimensional view of external spend.

This centralization has huge implications for tackling addressable spend and cash optimization, as 40 to 80 percent of a company’s total cost is wrapped up in external spend with suppliers.

Prepare your organization for procurement success in 2023

Centralizing data and automating processes are keys to weathering economic change. A procurement platform like Order.co offers organizations real-time data, features, and flexibility to make data-informed decisions and reduce the manual management of their procurement function.

- Centralized procurement with automation that enables future-ready matching across the p2p cycle

- Approval and role-based purchasing guidance to ensure every purchase is fully vetted and compliant with documented policy

- Features for accounting process improvement, reduced manual work, stronger spend analysis, and fast and flexible payments to vendors

If your procurement function is ready to make future-focused improvements to ensure stability through 2023 and beyond, request a demo of Order.co.

Get started

Schedule a demo to see how Order.co can simplify buying for your business.

"*" indicates required fields

A solid, repeatable procurement process is essential for optimal financial and operational function. The right approach speeds projects along and provides everyone with the tools they need while keeping budgets in check.

But what are the vital steps in a well-managed procurement process? How can you track the performance of your procurement practice to know you’re getting the best outcomes?

Let’s look at the stages and steps necessary to establish an effective procurement process. We’ll also cover different types of procurement and share the most effective KPIs to track your process and ensure your process adequately meets business needs.

What is procurement?

Procurement is the process of sourcing, buying, and paying for materials and services within a company. It’s a critical business function that allows companies to run more efficiently while ensuring everyone has the tools, materials, and software to be productive and effective.

Good procurement management enables the company to realize cost savings through strategic buying, improve supply chain management, and shorten manufacturing timelines.

Difference between indirect, direct, and service procurement

Though all purchasing moves through the same procurement process, several distinct categories exist. Each requires different methods of cost control and management.

The three main procurement types are direct, indirect, and service procurement.

- Direct Procurement: Purchasing goods or software tied to the production of a specific product. Examples include raw materials, equipment, resale items, machines, or other supplies.

- Indirect: Purchasing goods or software for overhead purposes (not tied to a specific product). Examples include office supplies, fixed assets such as desks, computers, and facilities-related items. It may also include software tools for general use (i.e. Slack or Zoom).

- Service: Procurement of non-employee consulting for either direct or indirect applications. Examples include legal services, contract-based and freelance services, and managed services like security and facilities, etc.

Stages in the procurement process

Procurement is a continuous process, but each purchase goes through three phases:

- Sourcing: The organization identifies the needed goods or services, begins the purchase request and approval process, and evaluates potential suppliers.

- Purchasing: Procurement negotiates with the chosen supplier, creates and transmits the order, receives the goods or services, evaluates goods received and supplier performance on the delivery, and accepts (or rejects) the order.

- Payment: Accounting performs three-way matching between invoice, PO, and requisition, approves and submits an invoice for payment, and completes post-close record-keeping.

Steps in the Procurement Process

1. Identify a need: The stakeholder or department head realizes the need for a product, software tool, or service. This purchase may fulfill an ongoing need (for instance, restocking consumables like office supplies) or a single purchase that supports a new project. These may be planned as part of the annual budget and procurement planning process or a spot buy of an unanticipated need. Once the stakeholder identifies a need, they outline the requirements to fill it, documenting it in a request.

2. Issue a Purchase Requisition: Using the information surfaced during the identification step, the stakeholder creates a purchase requisition or intake form. This is the formal request to procure the goods or services and includes all necessary information for ordering and payment. Depending on the type of procurement, the purchase req offers suggested solutions. For example, in a software purchase, the stakeholder may include three tools for evaluation.

3. Departmental Review: Once the purchase request is made, several departments may sign off on the purchasing decision. Often, the department head, legal, security, and IT departments have particular requirements to mitigate risk and ensure compliance for purchases. This review is especially important when engaging with new suppliers.

4. Budget Allocation: Once the necessary approvers complete their review, deals proceed to the finance team for approval and budget allocation. For small or one-off purchases, finance may approve a spot buy and direct the stakeholder to complete the purchase. From this point, finance or procurement may take over the negotiation for larger, contract-based purchases.

5. Request for Quotation (RFQ): The negotiating team will request quotes — or in some cases, a Request for Proposal (RFP) — from several potential suppliers to evaluate large purchases such as high-volume goods, consulting services, or software. This practice is commonly referred to as “three bids and a buy.” This allows the team to understand each solution better, explore features and pricing from different bidders, and conduct due diligence before negotiation. In some cases, at this stage of the purchasing process, the team may choose to work with a preferred list of suppliers selected as part of a strategic sourcing program.

6. Contract negotiation: Based on the numbers and contract terms provided, the procurement team engages the selected supplier to work out needs and requirements. During the negotiation, the team attempts to negotiate for the best price and payment terms, ensuring that they get the right-sized solution to satisfy the purchase request. If the negotiating team and supplier reach acceptable terms, the buyer executes the contract and transmits an approved Purchase Order to complete the transaction.

7. Receipt of goods: Working from the information in the PO, the supplier fulfills and delivers the goods or services to the buyer. Once delivered, the buyer inspects the goods for quality and accuracy. If the goods do not match the PO or have quality issues, the buyer may return them or seek a remedy through the supplier. The buyer should note any discrepancies between the order and the goods delivered for future record-keeping activities.

8. Matching process: The buyer performs three-way matching between the purchase requisition, purchase order, and invoice to ensure accuracy. This triple-check is necessary to address any discrepancies in the goods delivered and the amount to be paid.

9. Invoice approval: Upon a successful three-way check, the invoice is approved for payment, coded by the accounts payable department, and submitted for payment.

10. Payment: The buyer transmits payment to the supplier through preferred means (preferably electronically). If paid early, the buyer realizes early payment discounts.

11. Post-close recordkeeping: After successful payment, teams conduct record-keeping activities to facilitate analysis and future planning efforts. These activities include supplier evaluation, contract management, spend reporting, etc.

Track your procurement process with the best KPIs

One way to streamline your procurement strategy is by tracking metrics to understand your process and its outcomes. These metrics are called Key Performance Indicators (KPI). By establishing and monitoring your business KPIs you improve your process, shorten the procurement cycle and boost the bottom line.

Some key KPIs you’ll want to consider tracking are:

Cost per invoice (CPI): The cost to process an invoice for payment. This KPI tracks the efficiency in the payment stage of procurement. Manual processing is associated with higher CPI. Automation reduces the cost per invoice by increasing processing rates and reducing exceptions.

Invoice exceptions: The percentage of invoices encountering coding, processing, or payment errors during the purchasing process. Exception rates average 5% for most organizations. Rates above this level indicate problems in your invoice and payment processing workflow. As with CPI, automation significantly reduces this number.

Emergency purchase: The number of non-planned spending events within the measurement period (per quarter or year, for example). These unplanned events may point to issues with your project planning, budget, or requisition process. Problems with these processes could encourage maverick spending, increase risk, and reduce capital efficiency.

Vendor defects: The percentage of damaged or non-conforming items in a vendor delivery. Along with other supplier-focused KPIs, the defect rate could point to the need to offboard a particular vendor or improve the strategic sourcing program in your organization.

Procurement life cycle: How long a need takes to get from purchase requisition to settlement. Long lead times will impede production schedules and contribute to downstream distribution and cash flow issues.

Improving procurement process KPIs with automation

Once organizations begin improving and tracking procurement through KPIs, many discover areas of needed improvement. The most effective solution is not to increase headcount or complexity but rather to implement a scalable solution using procurement software. Doing so saves money on employee wages, reduces errors, and creates a process that grows right along with company growth.

If automation could improve your most crucial procurement KPIs, then the time is right to consider a solution that works for your organization.

Order.co helps organizations move away from tedious and error-prone manual processing and get a handle on spending and payment with an easy-to-use platform. Schedule a demo today to learn more.

Get started

Schedule a demo to see how Order.co can simplify buying for your business.

"*" indicates required fields

Every organization engages in some level of procurement strategy, whether using an ad hoc process or administering a large, well-documented procurement practice. While managing and tracking procurement spending may vary, how the process is defined shouldn’t.

But how do organizations define procurement? And is the definition of procurement important to company success?

To answer these questions, we’ll help you gain a clear understanding of procurement, including:

- What it is, its importance to your business, and the steps necessary for a successful procurement strategy

- How using procurement technology can significantly reduce the time and expense of successful procurement management

- How to improve the procurement cycle in your organization

- Real-world examples of how Order.co helps fast-growing companies achieve streamlined and automated invoice and procurement management

Download the free ebook: The Procurement Strategy Playbook

What is procurement?

Procurement is the process of sourcing, acquiring, and paying for goods and services. While many organizations use terms like ‘procurement,’ ‘purchasing,’ and ‘sourcing’ interchangeably, these are different components of the total procurement function.

Purchasing focuses on ordering and delivery, and sourcing pertains to the suppliers used for purchasing goods, but procurement refers to the entire process. Procurement includes sourcing, acquisition, settlement, analysis of procurement data, and future-spend planning.

Why is procurement important in business?

Every business requires materials, goods, and services to achieve its desired outcomes. Whether it’s software for communication, raw materials for making products, or services to maintain facilities, keeping the organization running is an expensive and time-consuming task.

The primary mission of a procurement department is to acquire the goods a business needs at the best price and terms. Procurement professionals excel at building supplier relationships, negotiating advantageous terms, and streamlining the procurement process, from identifying a needed good or service to invoice payment.

With a streamlined procurement process, organizations increase cost savings, minimize wasteful spending, and analyze how and where budgets are most efficiently deployed. Automated procurement can help businesses save as much as $13 or more per invoice in processing costs. The money preserved through good procurement practices spurs growth and insulates the organization against downturns.

Types of Procurement

Companies engage in different types of procurement, depending on business needs and immediate goals.

Direct procurement: This is the acquisition of goods and services directly related to production within your organization. Examples include the raw materials, software, services, or products that directly support the production of the products your company sells.

Indirect procurement: Anything not directly related to the production of goods is indirect procurement. This category includes office supplies, software the company uses to communicate internally, or facilities services not connected to a specific product your company offers.

Whether direct or indirect, companies require two types of purchases: goods procurement and services procurement.

Goods procurement: Goods procurement refers to any tangible object purchased, whether finished or unfinished. Raw materials, office supplies, desks, and other physical goods are considered goods procurement.

Services procurement: Any non-tangible purchase falls under services procurement. This includes professional offerings such as consulting services or facilities repair. It also encompasses purchases such as software, with software as a service (SaaS) increasing in business use and often becoming one of an organization's most significant service-based expenditures.

How procurement works

Strong procurement management is one of the most critical components of an organization’s financial health. Procurement is often one of the most substantial portions of revenue spending, so it’s essential to keep a careful eye on expenditures at a granular level. This level of spending optimization requires a cross-departmental effort that draws on oversight from finance, legal, IT, and supply chain management stakeholders.

The procurement team may seem like an intermediary between internal stakeholders and suppliers. In reality, the department is responsible for the continuous administration and improvement of the procurement process and supplier lifecycle.

There are many stages of the procurement process. Most procurement and purchasing activities fall into some general categories, including:

Planning: The planning phase includes establishing budgets for departments or teams. This process happens in cooperation with the finance team and departmental stakeholders.

Sourcing: Sourcing encompasses using competitive analysis and current strategic sourcing partnerships to identify the best suppliers to meet company needs. This evaluation process is conducted in conjunction with department heads and purchasing approvers.

Acquisition/payment: This stage includes ordering, reconciling, and paying for goods and services and meeting organizational needs while maintaining spending control. Such close attention to price and terms ensures the acquisition of the best quality products at competitive prices and under the most favorable terms.

Evaluation: Evaluation means using past performance and current data to understand and strengthen supplier relationships, prepare for future spending, and analyze available data to uncover further cost savings and improve the bottom line.

Steps in the procurement process

Procurement practices are most effective when they follow a repeatable, optimized process. While every procurement team establishes a unique process for sourcing, acquiring, and paying for goods and services, the procurement cycle usually follows the following steps:

- Identify a need: A stakeholder surfaces the need for a product, materials, software, or service in order to create products or conduct daily business. This need is outlined in an intake form or requisition form.

- Submit a purchase requisition: The stakeholder completes a purchase request. This form should include all relevant information needed to approve and process the purchase. The requisition may include recommendations for solutions or service providers.

- Evaluate potential suppliers: Depending on the process and type of purchase requested, procurement evaluates possible solutions and selects the best vendor to fulfill the request. Sometimes this takes the form of a competitive bidding process, such as a request for proposal (RFP), request for quote (RFQ), or a “three bids and a buy” process.

- Negotiate terms and conditions: Once the best supplier has been selected, the negotiation process begins. The procurement team works with the sales rep to establish pricing and terms for the purchase. Negotiations should be completed only after all departmental prerequisites have been met.

- Create a PO: Procurement drafts a purchase order to acquire the goods or services from the supplier. In most cases, the PO goes through a separate approval process to ensure all transactions meet expectations and check for potential issues or discrepancies. Procurement then transmits the purchase order to the supplier for fulfillment.

- Receive and review goods: The supplier fulfills the order as requested. Once the goods or services are delivered, the procurement team receives and inspects them to ensure the quality and accuracy of the shipment. If the order does not meet expectations, the receiver may seek adjustments from the supplier or return the shipment.

- Reconcile and match: After receipt of goods is complete, a three-way match is conducted to ensure the shipment, invoice, and PO are accurate. The procurement team also conducts supplier evaluations to ensure all expectations and contact conditions are met during the delivery process.

- Approve and pay the invoice: Once three-way matching is complete, the supplier invoice is submitted for processing. The invoice is batched, coded, and scheduled for payment.

- Complete post-close activities: The procurement team is responsible for post-close operations and purchasing analysis. This may include record-keeping, reporting, spend analysis, supplier evaluation, contract management, and supplier onboarding (in cases where contracts are completed or terminated).

Case study: How Order.co helped WeWork automate procurement

The procurement process at small companies often starts out with a simple, manageable workflow. Some accounts payable (AP) teams can get by with manual processes for a time. But what about a company that experiences explosive growth? That success often comes with exponential growth in orders and invoices.

This was the case for WeWork. The unicorn coworking company’s meteoric rise saw the addition of over 800 global locations in a few short years. It also added invoices — over a million per year and rising. The scale of operations left too much space for out-of-policy spending and surprise invoices that caused confusion and cost money. The company needed a way to streamline and automate processes for more than 2,400 orders per month across 100+ vendors.

WeWork turned to Order.co in 2017 to eliminate its manual processes and automate its procure-to-pay process. With our help, the company created a fully functional, automated system integrated with Workday to get spending and processing under control. The changes created detailed spend visibility across every location and category, greatly reduced WeWork’s cost per invoice, and resulted in a simple, dynamic process that controlled budgets while allowing stakeholders to get needed supplies.

To read the whole story of how WeWork used Order.co to revolutionize its procurement process, see the full case study here.

How Order.co can help manage procurement

Maintaining a streamlined procurement process and analyzing data is no small feat. Even in new and growing companies, procurement may deal with dozens of vendors and thousands of invoices. This generates an excess of data that can only be fully utilized with the help of technology.

Using procurement management software to automate processes and centralize the data reduces the strain of manual procurement processes, and allows teams to understand how the organization spends money.

Order.co can help improve the purchase-to-pay process by:

- Allowing businesses to analyze and contextualize purchasing data in order to set more accurate budgets and plan capacity effectively.

- Streamlining the vendor selection process and empowering buyers to use strategic sourcing partners when acquiring goods and services.

- Centralizing contract, benchmarking, and supplier data to create better leverage in negotiations.

- Automating three-way matching and reconciliation to reduce effort and time spent on the process.

- Streamlining the invoicing and vendor payment process to reduce manual data entry, eliminate invoice exceptions, and integrate and consolidate vendor payments.

When you define procurement processes in your organization and empower your organization with the benefits of a robust procurement platform, the savings and productivity quickly add up.

To get a better understanding of how Order.co can help your organization, schedule a demo and see the platform in action.

Get started

Schedule a demo to see how Order.co can simplify buying for your business.

"*" indicates required fields

Better systems are the key to better results, especially when your organization is on a growth track. A robust procure-to-pay process (P2P) is one of the most beneficial systems to speed progress while retaining visibility into spending.

But how can you be sure your procurement and purchasing processes are optimized? What does an effective procure-to-pay process look like? How can automation ensure that spending remains under control as you grow?

Download the Free Guide: Choose the Right Procurement Technology With This Decision Matrix

We’ll take a detailed look at what goes into a successful purchasing workflow. We’ll also cover some best practices that can tighten up the process. Lastly, we’ll show you how automation can help you keep your procure-to-pay process functioning without breaking a sweat.

What is procure-to-pay?

P2P is the systematic process an organization uses to identify, request, and pay for the goods, products, and services required to run the business.

Procure-to-pay does not encompass the entire procurement function. It focuses on the purchase, reconciliation, and vendor payment portion of the process.

Activities such as strategic sourcing, lifecycle evaluations, vendor off/onboarding, and supply chain management fall outside the scope of procure-to-pay.

The 9 steps of an effective procure-to-pay process

The benefits of a standardized, repeatable procure-to-pay process in your organization cannot be overstated.

Having a streamlined workflow in place reduces maverick spending, makes the purchase process faster, improves your order and supplier management, and increases productivity and satisfaction for stakeholders.

The general flow of the procure-to-pay process is as follows:

- Identify a business need: A stakeholder realizes the need for a product or service to perform their job. They may evaluate services or identify the product or materials that work best.

- Request the item/service: The stakeholder then puts together a requisition or intake form to formally request the purchase of goods. This requisition kicks off the approval and purchase process.

- Receive requisition approval: The requisition goes through a standard approval process and receives sign-off from all pertinent stakeholders or departments. Finance allocates money for the purchase.

- Create purchase order: After approval, the relevant stakeholder creates a formal purchase order (PO) to procure the goods. This PO will have all the necessary information for order processing and delivery of goods.

- Receive purchase order approval: Although the requisition has received approval, the completed PO will ideally undergo a separate evaluation and approval process. This helps reduce errors, clarify requirements, and ensure a smoother purchase and reconciliation process. Once approved, the PO is transmitted to the supplier for fulfillment.

- Receive the items/materials: The order is fulfilled and delivered by the supplier. The receiving party inspects and evaluates the delivery and checks for accuracy against the order. In cases where the goods don’t match the order or meet quality requirements, the receiver may reject the order.

- Evaluate vendor performance: Once receipt and reconciliation of goods is complete, a performance review is conducted. This should evaluate aspects of the purchase, including on-time delivery, order accuracy, quality/condition of goods, etc. Any issues can be noted during this evaluation and used during subsequent purchasing decisions.

- Invoice approval: At this point, a three-way matching process begins to ensure the delivered goods are accurate to the purchase requisition, purchase order, and invoice. Once invoice matching is complete, accounts payable can start invoice processing.

- Pay the Supplier: This is the final step of the procure-to-pay process. The approved payment is submitted to the supplier based on the purchase order or contract terms. In some cases, timely payment of invoices can help the organization realize benefits such as early payment discounts.

3 best practices for improving your procure-to-pay process

Improve your business processes, maximize outcomes and make your purchasing and payment functions work better with three highly-impactful best practices.

1. Build a standard approval process for every purchase

Outlining a formal process for requesting and purchasing goods balances your organization's need for oversight and compliance with the need to support your staff and avoid hindering their progress.

A well-documented procure-to-pay process:

- Creates a frictionless environment where your employees get what they need without uncertainty. It allows staff to remain productive and feel supported in their role.

- Ensures consistent oversight into purchases and adherence to budgets and departmental prerequisites.

- Reduces risks of ordering from unknown suppliers or making out-of-process, unsanctioned purchases

- It increases visibility, reduces redundancy, and allows finance to track, analyze, and forecast spending

Your process doesn’t have to be elaborate. It should lay out the path to approval and set expectations for requestors. It should be easy to implement, track, and repeat for every purchase, and enhance the procure-to-pay cycle to ensure continuous improvement of these functions.

At a minimum, your purchase approval process should include:

- A standard requisition or intake form with all required information spelled out.

- A first point of contact or process owner to begin the requisition and approval.

- Clearly defined approvers and approval parameters for each purchase.

- A system to track and document requisitions and orders as they go through the process.

- A post-close process for evaluating purchases, strengthening beneficial supplier relationships, and offboarding vendors at the end of service

2. Outline your contract and departmental requirements

Each approving department in your purchasing process likely has standard requirements for its purchase requisitions. These prerequisites are essential for ensuring high-quality procurement while reducing risk. However, stakeholders and purchasers can only meet these requirements if they know what they are. The specific requirements will be unique to each organization and their individual strategy, but form an important part of the decision-making process and ultimate outcome of the request.

Some examples of possible departmental requirements:

- Internal department lead: Preferred supplier or integration partners based on current tech stack or other partner agreements.

- Legal: specific terms or clauses to enforce adequate contract protections cover to common issues like service-level agreements (SLA), downtime clauses, disaster recovery responsibilities, arbitration, etc.

- Security: Completion of a supplier questionnaire to determine security and risk management thresholds.

- Finance: Preliminary budget estimate or project milestone report to aid budgeting and forecasting.

To ensure a smooth approval process, document and outline these requirements in one place.

Making departmental requirements part of the intake process helps stakeholders acknowledge and fulfill them before a requisition even enters the pipeline. This reduces friction, avoids purchasing delays, and ensures high quality for every purchase your company makes.

3. Consider automation

As organizations grow, the purchasing process grows exponentially along with them.

As growth increases, so does contract management for dozens or hundreds of vendors. In a short time-frame, departments begin processing hundreds or thousands of monthly invoices across different locations. In a very short amount of time, your manual procure-to-pay process becomes backlogged and inefficient.

Rather than continuing to expand the headcount for these operations, consider implementing automation to handle the repetitive and manual tasks in your purchase-to-pay process.

Using procurement and AP automation can improve the purchasing experience for buyers while reducing the strain on procurement teams and AP departments. In addition, it can free up these important teams to conduct higher-value functions in the organization.

How does procure-to-pay automation software work?

Procurement software creates a centralized, automated workflow from item selection to invoice payment.

On the front end, the system automates the purchasing process for buyers through a cloud-based system that centralizes supply orders. Users access a curated catalog of items provided by a database of approved suppliers.

From there, they can order the goods they need within pre-set system budgets and parameters. This system is dynamic, giving administrators the ability to set spending rules by user, department, category, or location.

On the back end, procure-to-pay software automates many repetitive and manual processes. Purchases originating from the catalog are routed through an automated approval process. Once approved and delivered, invoices are checked and reconciled within the system, and payment for goods and services are scheduled automatically.

The system uses AI and machine learning to automatically process thousands of invoices, ensuring they are correctly routed, reconciled, and paid without manual input from workers.

E-invoicing also enables integrated payments for purchases.

How can procure-to-pay automation help?

Using an automated e-procurement system will improve every stage of your P2P process. By providing a centralized system for all your purchasing, you ensure that organizational requirements are observed while reducing the friction of fulfilling everyday needs.

With the right P2P solution, you will:

- Ensure adherence to budgets, purchasing guidelines, and approved vendor lists

- Improve supply chain management when ordering for multiple locations

- Reduce your cost per invoice and invoice exception rates

- Stabilize and improve cash flow by consolidating invoices and payments

- Help surface cost savings opportunities to improve the bottom line

- Provide real-time, line-level visibility into buying data for better spend management

The value of procure-to-pay software begins with improving productivity for teams and maintaining quality in purchasing. It also has the potential to drastically improve cost savings and reduce waste spending within your organization.

If you’re ready to learn how automated procurement with Order.co can help you achieve these outcomes, schedule a demo of the platform today.

Get started

Schedule a demo to see how Order.co can simplify buying for your business.

"*" indicates required fields